We offer a variety of metal heat sinks, including shovel tooth heat sinks, liquid cooled plates, and copper or aluminum metal substrates. Radiators can be processed into various shapes according to requirements.

Heat Sink

The main advantages of shovel tooth heat sink technology are reflected in structural design innovation, material performance optimization, and process efficiency improvement. Its shovel tooth technology integrates the substrate (aluminum/copper) into ultra-thin fins through high-precision cutting, breaking the 20 fold limit of traditional extrusion technology in terms of tooth height; The heat dissipation area per unit volume increases by more than 30%, and the fins have no contact with the substrate, avoiding thermal resistance loss and achieving 100% release of thermal conductivity; By using high-purity aluminum or copper aluminum composite materials, the corrosion resistance is significantly improved while maintaining lightweight. Applied in multiple fields, its ultra-thin high-density tooth structure can quickly export heat generated by high-power components such as 5G base station chips, graphics cards, and GPUs; The shovel tooth technology supports the processing of copper aluminum composite materials and achieves efficient heat exchange through microchannel water cooling head design. In new energy and energy storage systems, their lightweight characteristics are utilized to provide a reliable heat dissipation solution for battery pack thermal management systems with large dimensions and no welding points.

Parameter | Copper material | Aluminum material |

Thermal conductivity coefficient | 380-400 W/(m·K) | 201-210 W/(m·K) |

Density | 8.96 g/cm³ | 2.7 g/cm³ |

Cost | About three times that of aluminum | with lower cost and suitable for large-scale applications |

Processing difficulty | High (requiring precision brazing) | Low (easy to cut and stamp) |

Parameter | Copper material | Aluminum material |

Thermal resistance(1.5mm) | 0.004 K/W3 | 0.008 K/W3 |

Heat dissipation efficiency | High under the same volume 40-50% | Need to increase fin density compensation |

Applicable power | 10W~2000W,It is recommended to use liquid cooled plates for single modules above 2000W. | |

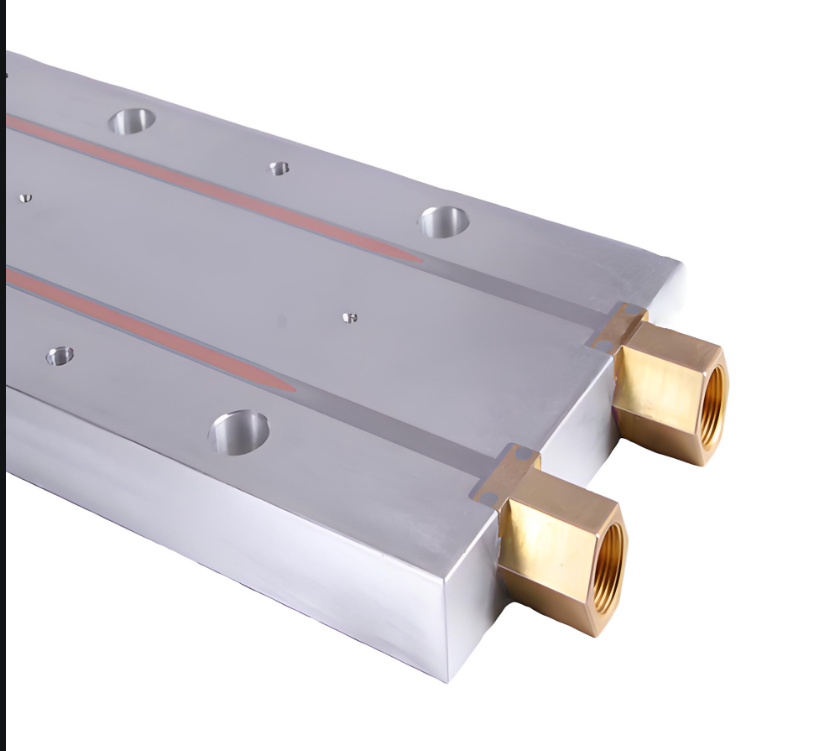

Liquild Cooled Plate

Liquid cooled plates mainly use aluminum material as the heat dissipation substrate. After slotting on the aluminum plate, copper pipes are embedded to quickly remove heat through the flow of liquid inside the copper pipes. Low noise, high heat dissipation efficiency, and the cold plate temperature can be controlled within a relatively constant range. Other advantages include: lightweight and high thermal conductivity balance, corrosion resistance, etc. It is widely used in high-power electronic equipment RF module, new energy vehicle battery module, 5G base station RRU unit, edge computing server, fiber laser output head cooling module, etc.

Parameter | Typical Value | Description | |

Substrate material | 6063 Aluminum alloy | Thermal conductivity of 200W/m · K | |

Copper pipe specification | Outer diameter of 10mm and a wall thickness of 1mm after flattening | | |

Channel design | Parallel channel/Serpentine channel | Serpentine channel improves heat dissipation uniformity by 20% | |

Contact thermal resistance | ≤ 0.01 K · cm ²/W | Epoxy resin adhesive filling reduces interface thermal resistance | |

Heat dissipation capability | Single board heat dissipation power: 200-800W | Depending on channel density | |

Temperature difference control | ≤ 3 ℃ | Deep buried pipe design | |

Weight | 1.5-3kg | Aluminum substrate+copper tube | |

Metal Substrate

We can provide copper or aluminum materials in various specifications and sizes as substrates for PCB or other modules that require fixing or heat dissipation. Its main technical feature is its ultra-high thermal conductivity, such as copper having a thermal conductivity coefficient of 398 W/(m · K); Excellent high-frequency performance, suitable for high-frequency circuits (such as 5G base stations and RF equipment), reducing signal loss; Matching the coefficient of thermal expansion, such as copper’s CTE (17 ppm/℃) being closer to silicon chips (3 ppm/℃), reduces thermal stress and improves reliability. Widely used in high-power density devices such as AI server GPUs, laser drivers, high-frequency switching power supplies, base station RF modules, microwave circuits, etc.

Parameter | Copper material | Aluminum material |

Material model | T2 pure copper (C11000) | 6061-T6/5052-H34 |

Thermal conductivity | 380-400 W/(m · K) | 200-220 W/(m·K) |

Density | 8.96 g/cm³ | 2.7 g/cm³ |

Conductivity | ≥ 100% IACS | 35-40% IACS |

Thermal resistance(1.5mm) | 0.004 K/W | 0.008K/W |

Heat dissipation efficiency | 40-50% faster than aluminum |

|

Shielding efficiency | High frequency shielding effect is better (skin effect) | Additional coating (such as nickel) is required to enhance shielding |

Customized Consultation

wechat: yao13521681306

whatsApp: +8613521681306

Email: wuyanlitong_002@126.com

Add: Room 301,Unit 1,Liandong U valley science and technology park. No.21,shuiyuan west road, Miyun district,Beijing China.